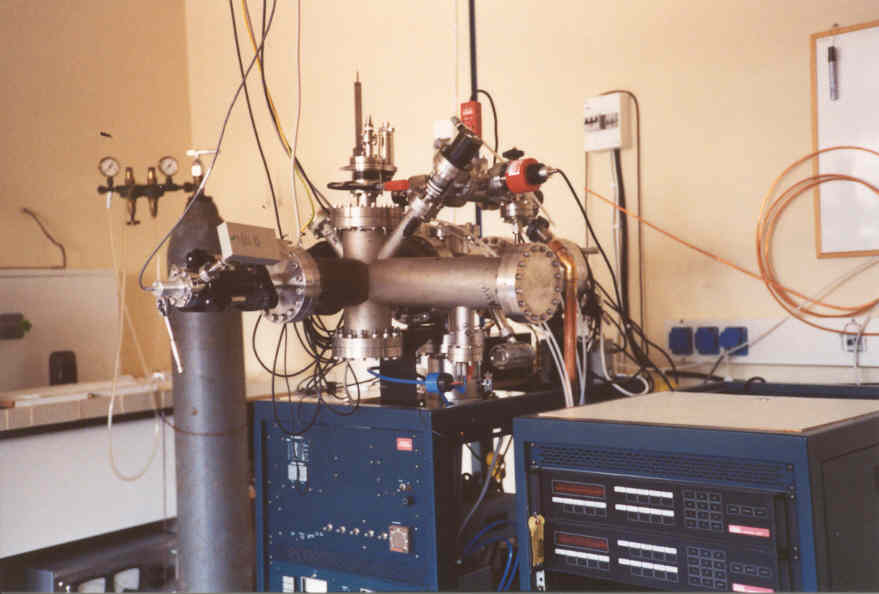

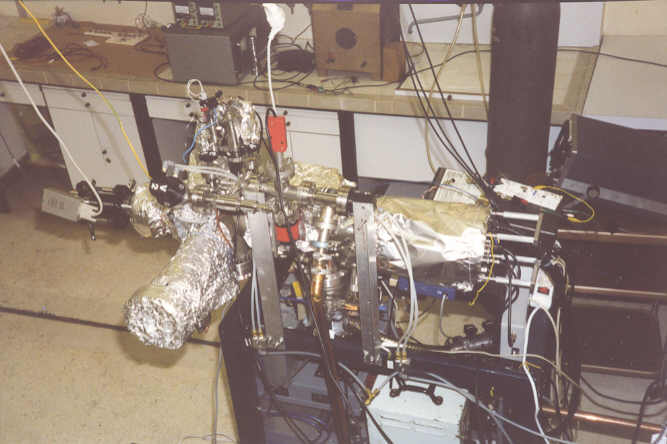

View of the lab (August 2000).

View of the lab (August 2000).

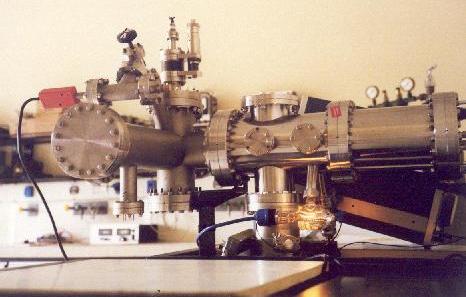

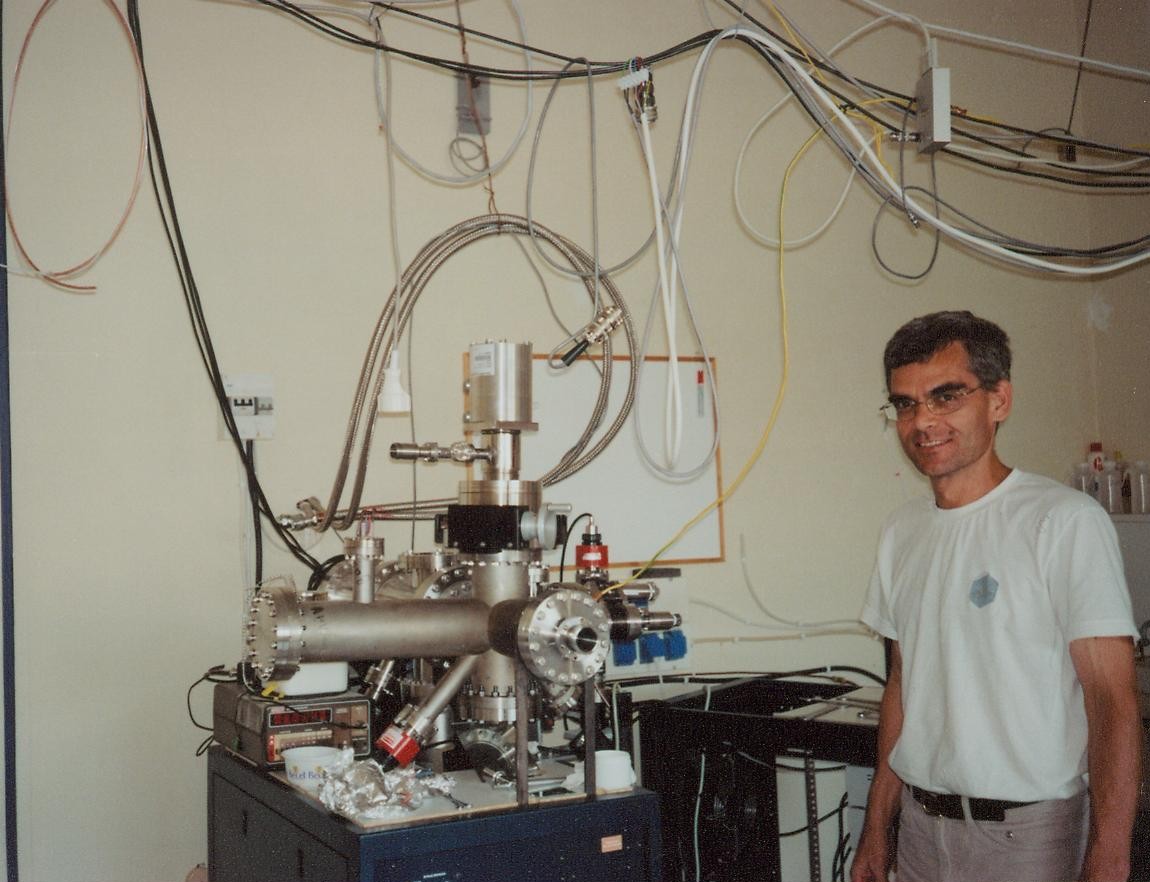

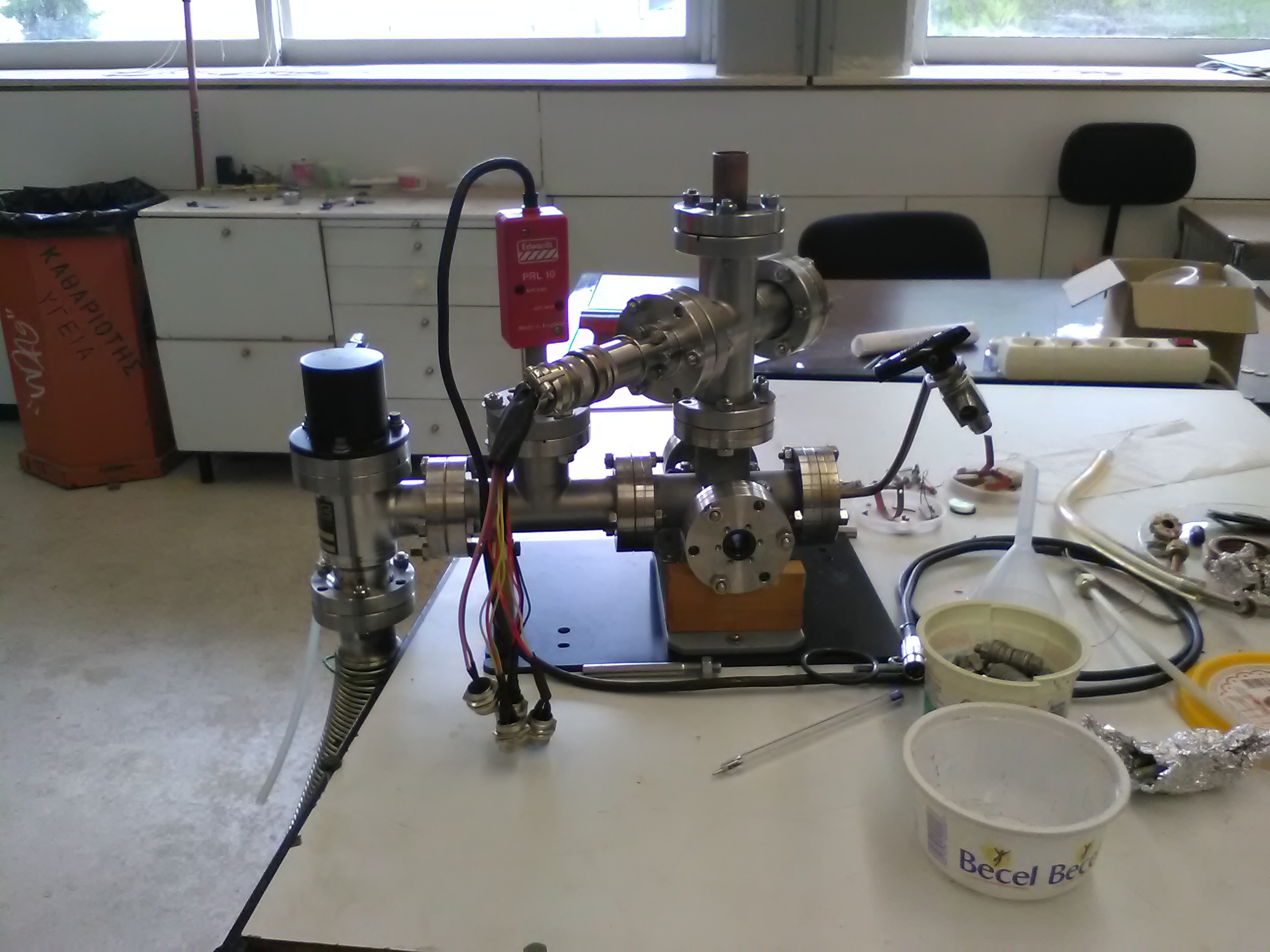

The mass spectrometer chamber (August 2000).

Kelvin probe on the shelf (August 2000).

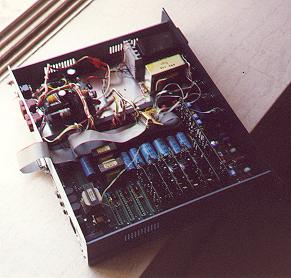

Modified mass spectrometer ionizer control (August 2000).

The electronics bench (August 2000).

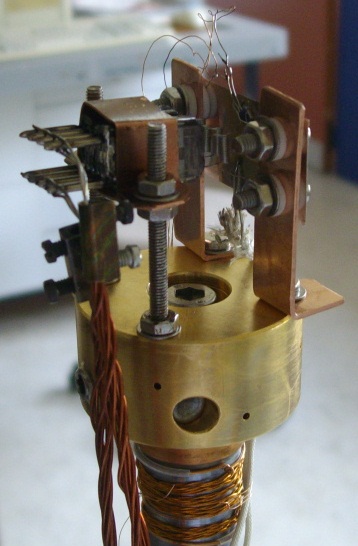

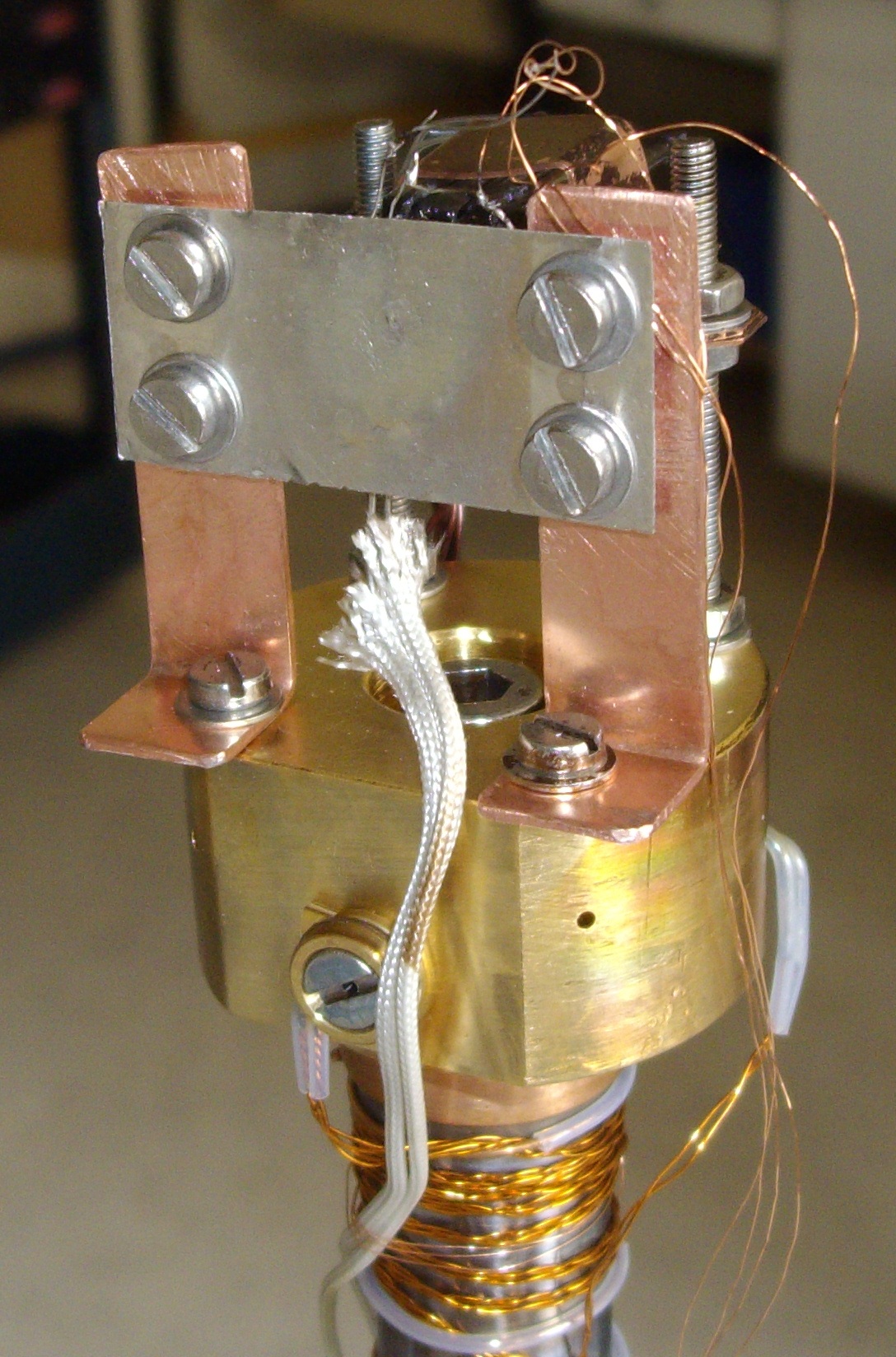

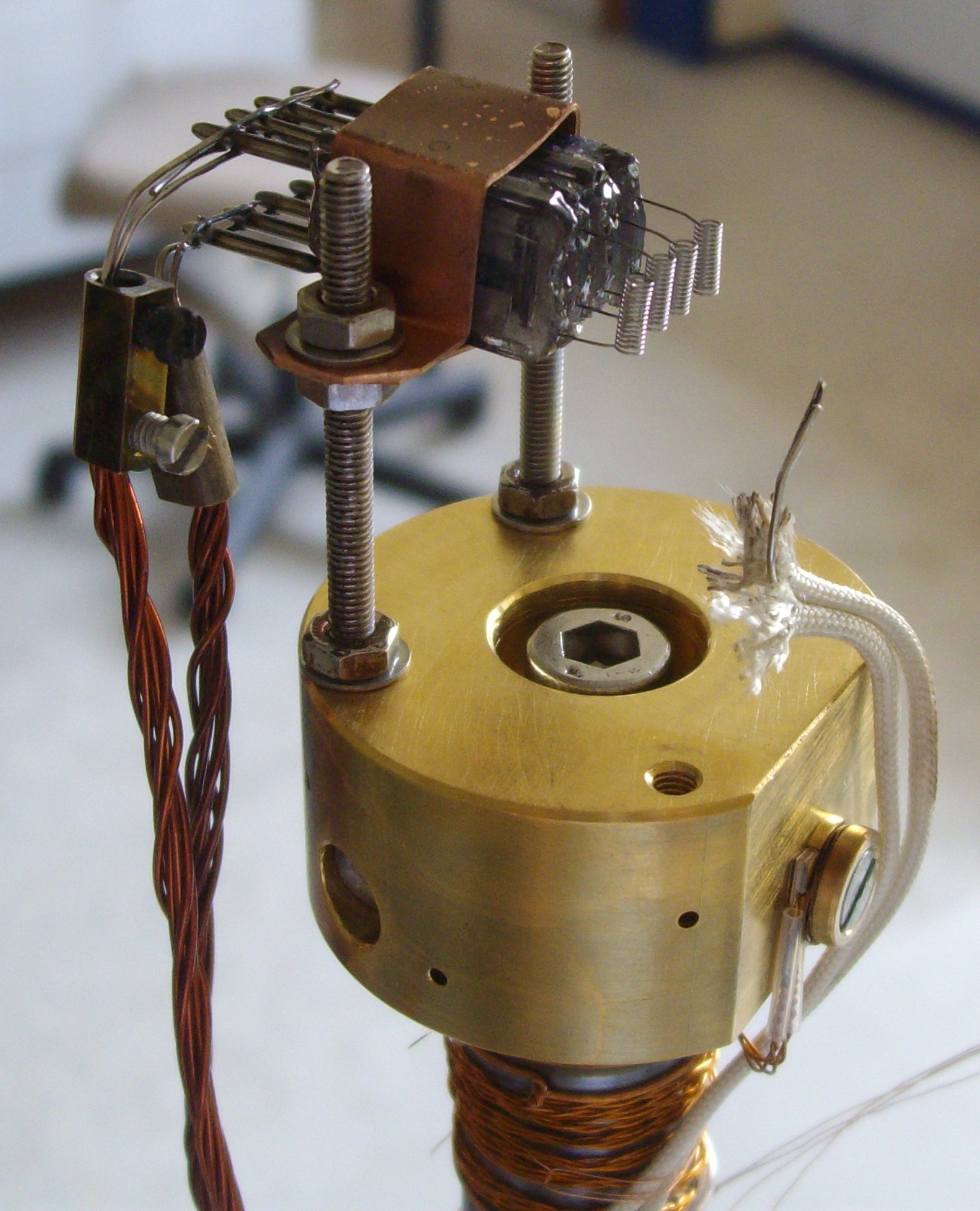

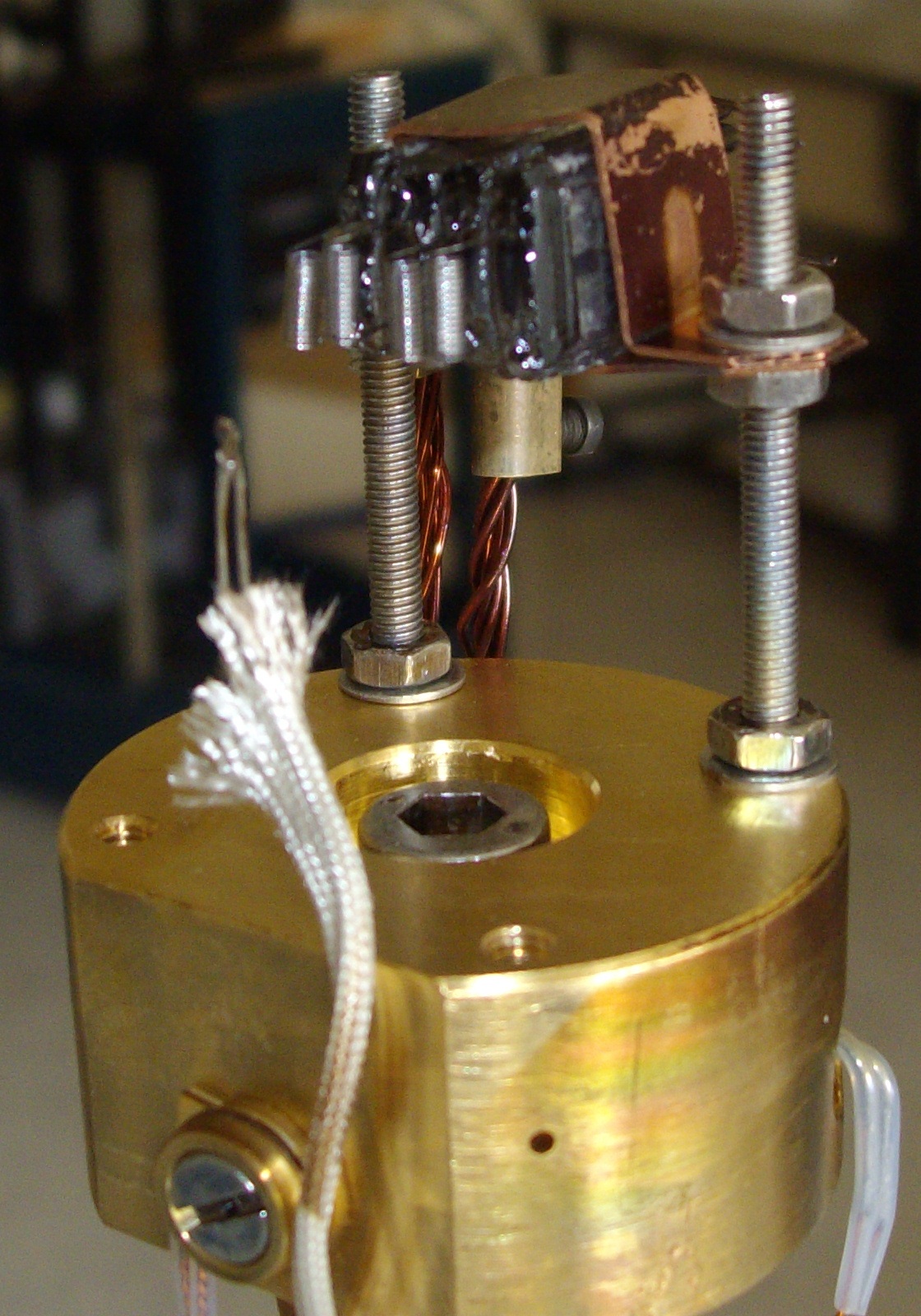

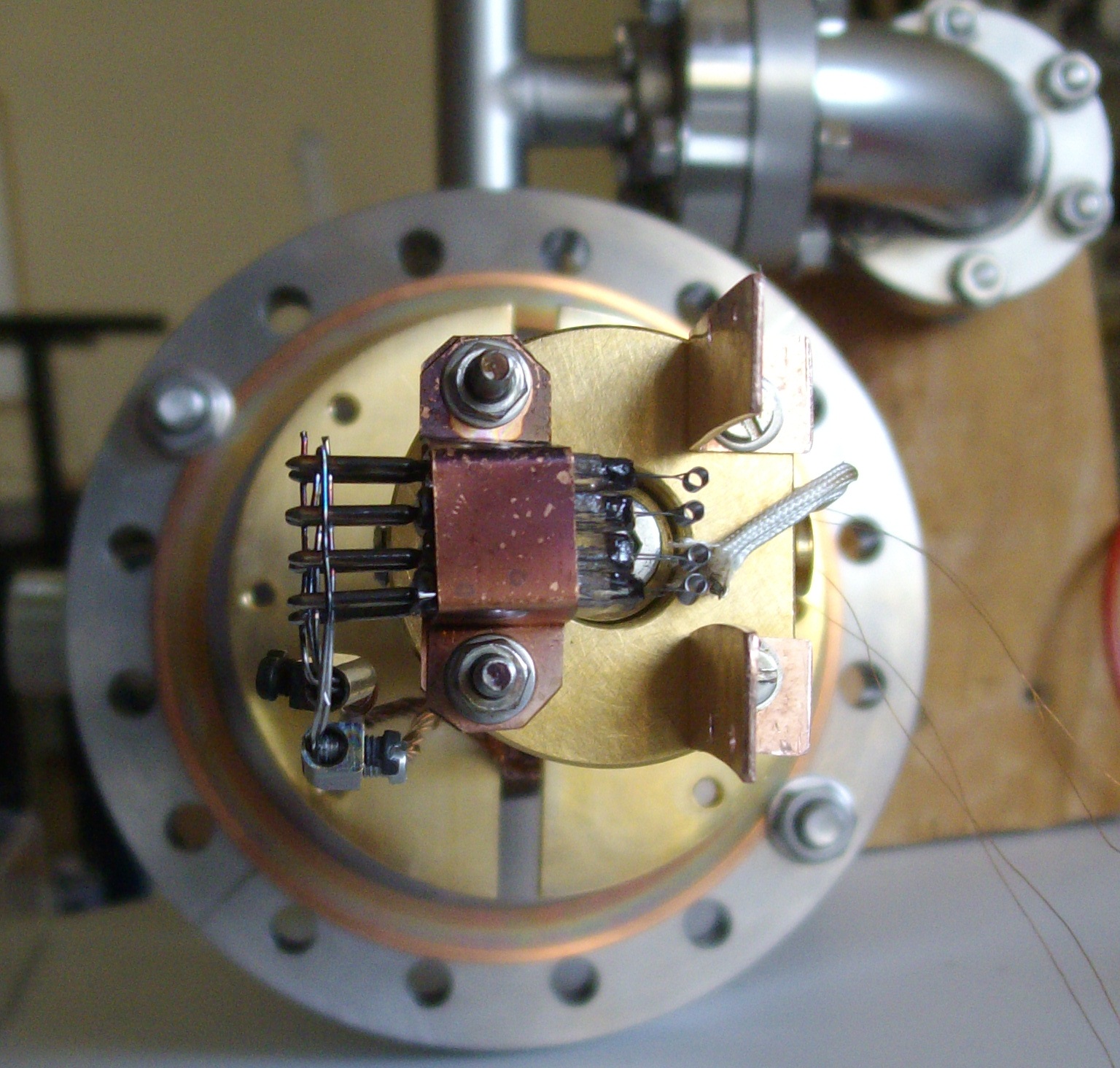

Cross chamber with primitive sample manipulator (front view) (November 2000).

13/8/2008

30/10/2009: The cpd offset box before dismantling for its parts to be used in an upgraded version.

3/11/2009: The new cpd offset box before final assembly and after it has been installed in place by the chamber.

21/12/2009: After another equipment upgrade: Copper tube delivering gases to the proximity of the sample can be heated and its temperature monitored.

19/1/2010: Researcher in action

30/5/2012: Replacing the bent Pt foil; found visible deposition marks on various places

1/6/2012: New Pt foil mounted on new Al bloc.

27/6/2012: Unmounting electrically insulated Pt foil set-up (due to poor heat conductivity).

28/6/2012: Mounting the latest sample on the sample holder, without electrical insulation

22/5/2013

14/6/2013: Mounting a new sample on the refridgerator.

19/6/2013: Same sample with Cu back cover for improved thermal contact.

2/9/2016: Snapshots of the chamber

9/9/2016: Electron screen built and moving into place

10/5/2017: Views of the machine, the electron screen and the sample from the side

23/8/2017: View of the machine and the modified gas-handling manifold

Cross chamber and mass spectrometer (side view) (November 2000).

Cross chamber with Kelvin probe attached (July 2001).

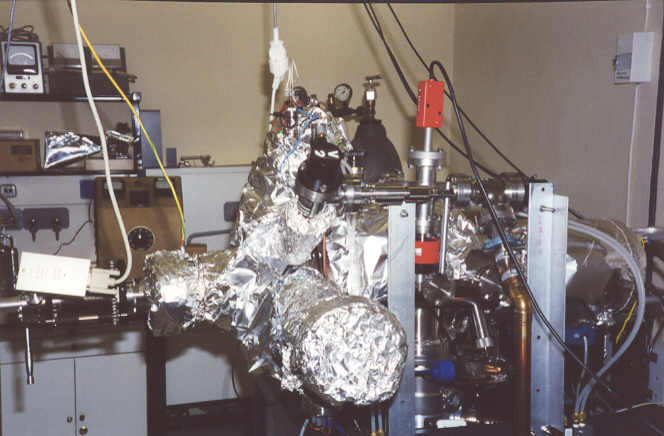

Bakeout time - side view with modified gas handling lines (December 2002).

Bakeout - aerial side view (December 2002).

Lab overview (December 2002).

View of the ionizer region of the mass spectrometer (December 2003)

Sample holder with LN2 attached to the bench for modifications (December 2003)

Sample holder with LN2 attached to the bench for modifications (December 2003)

View of the chamber after inverting the triple cross (December 2003)

View of the chamber after attaching the rotary flange at the top of the chamber for sample manipulation (December 2003)

15/8/2007

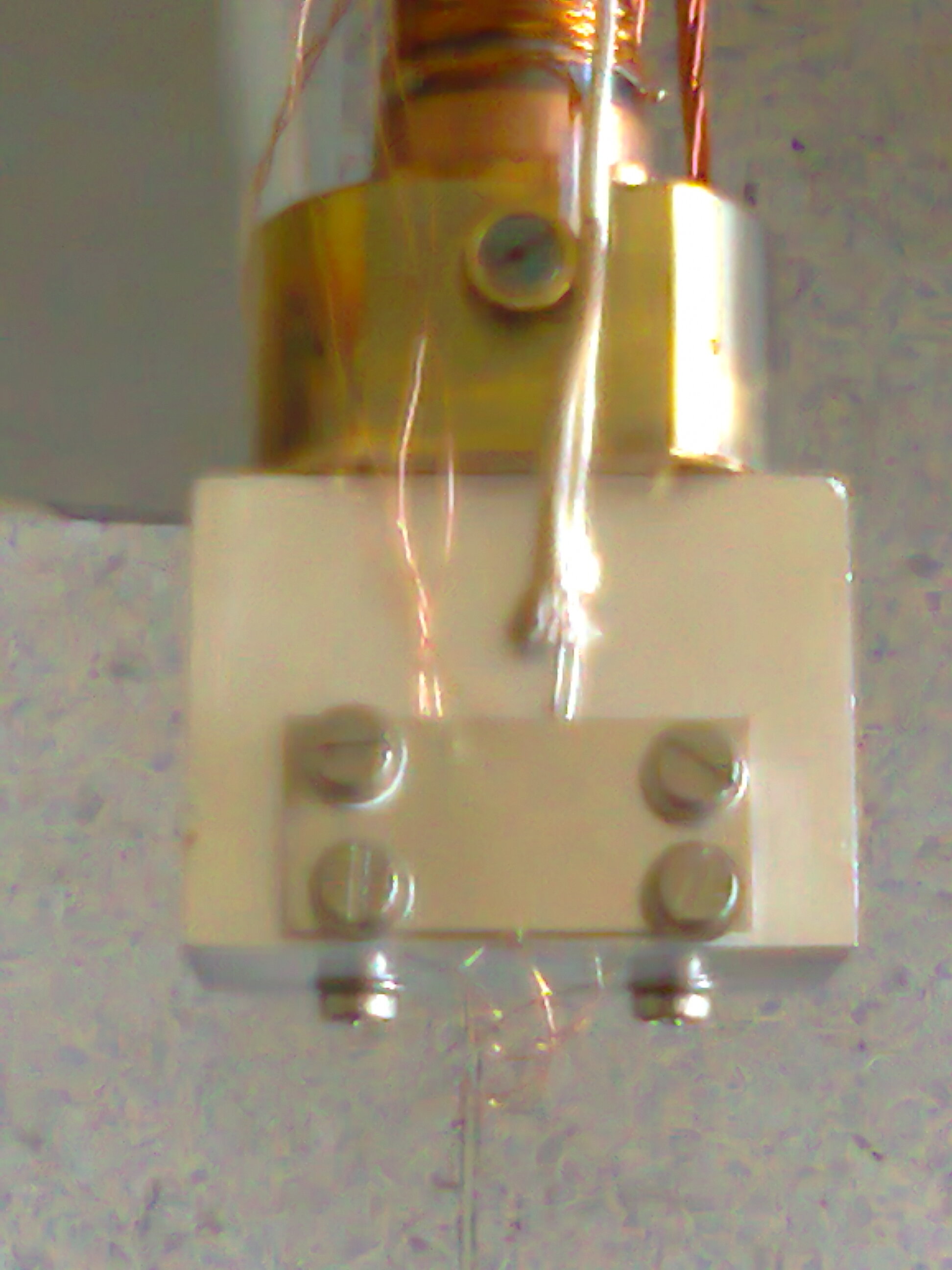

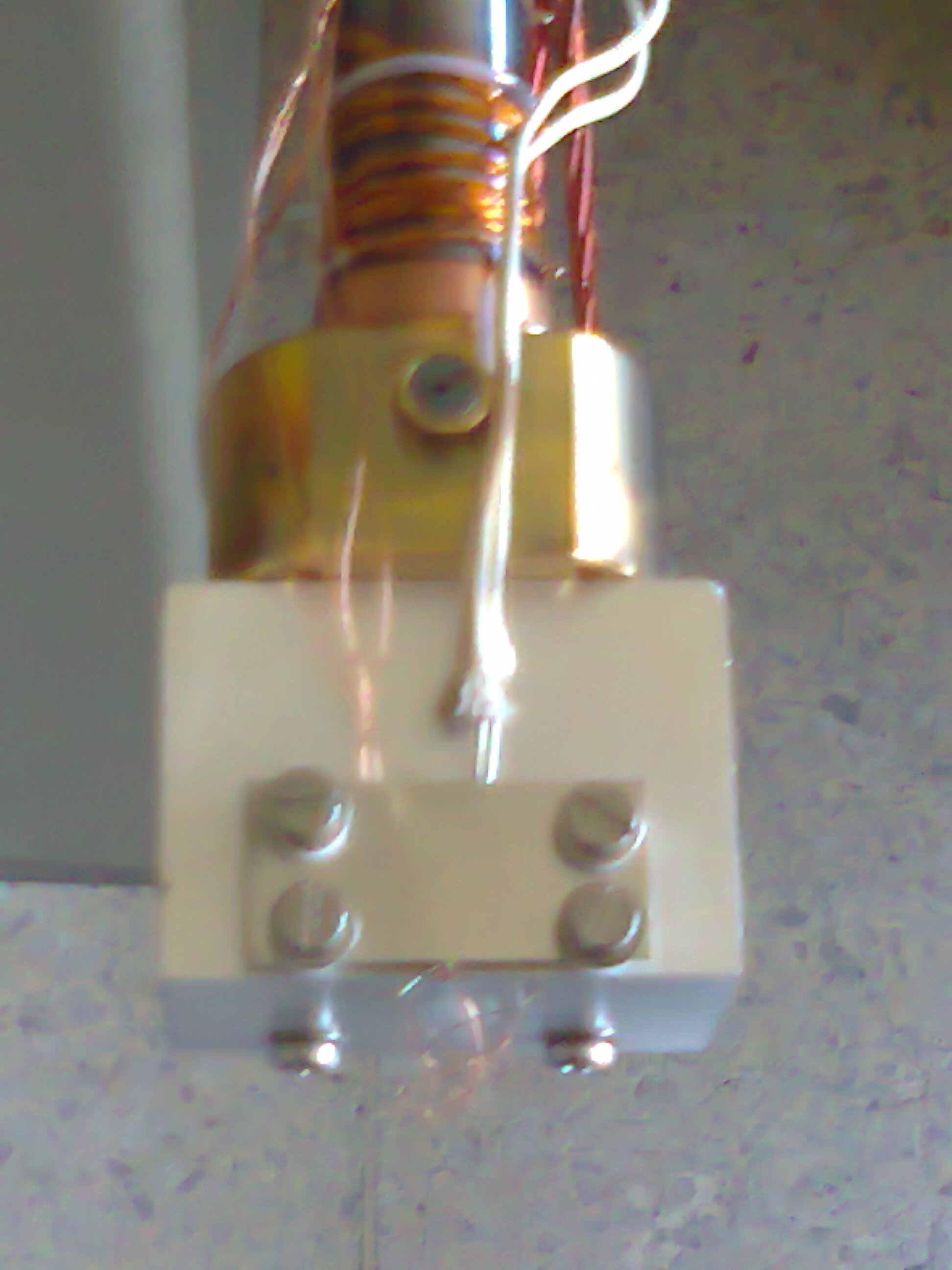

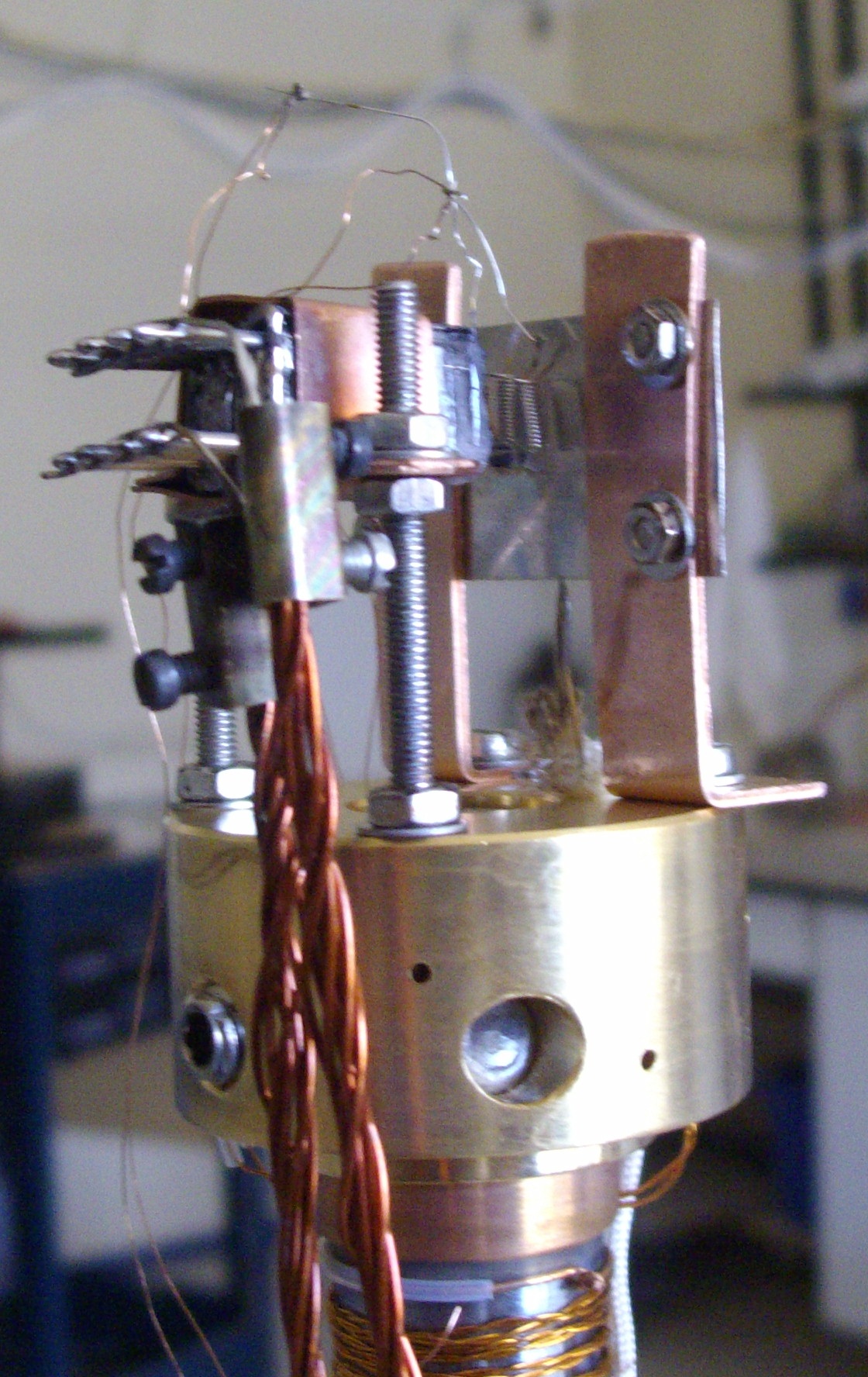

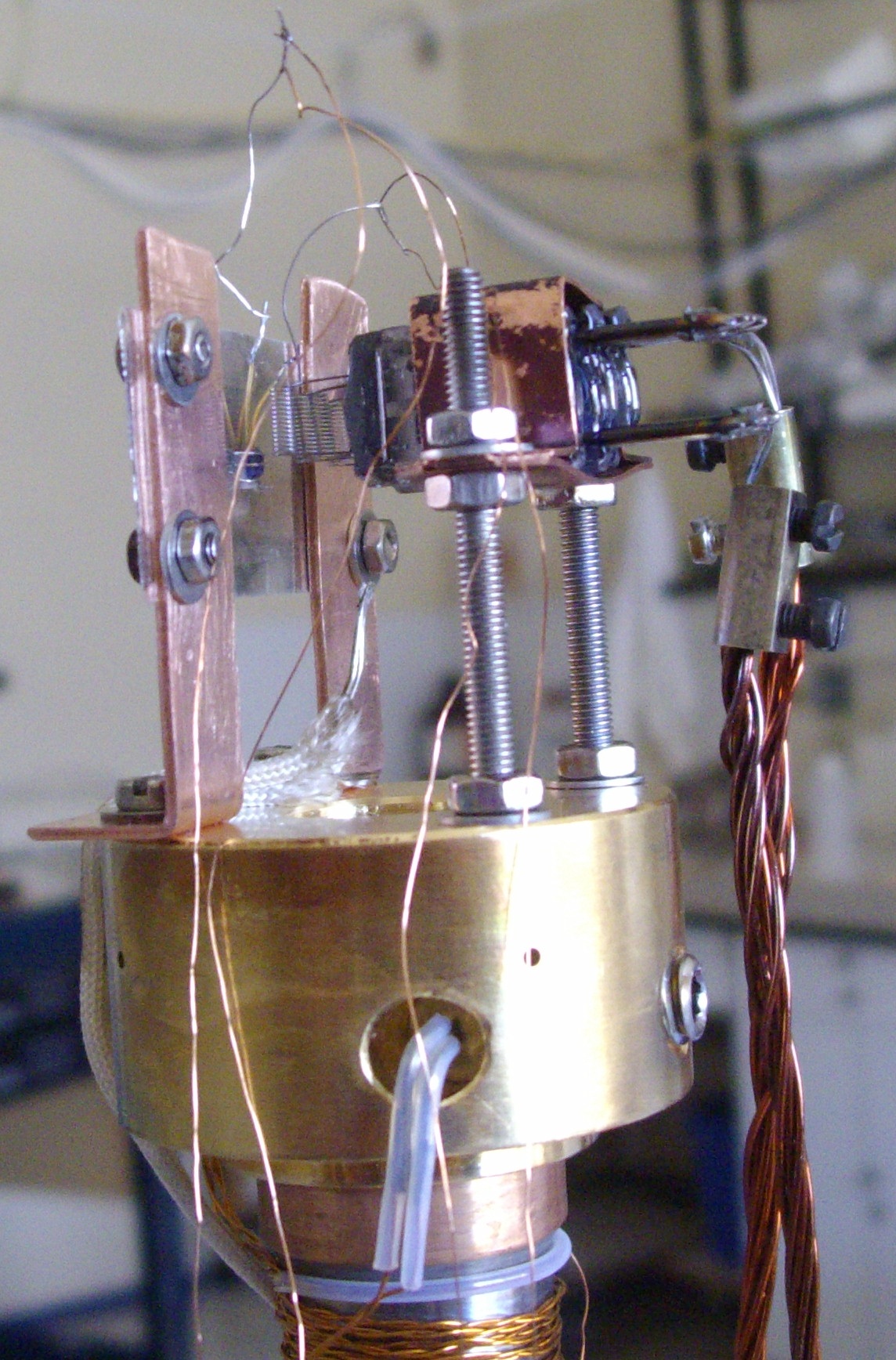

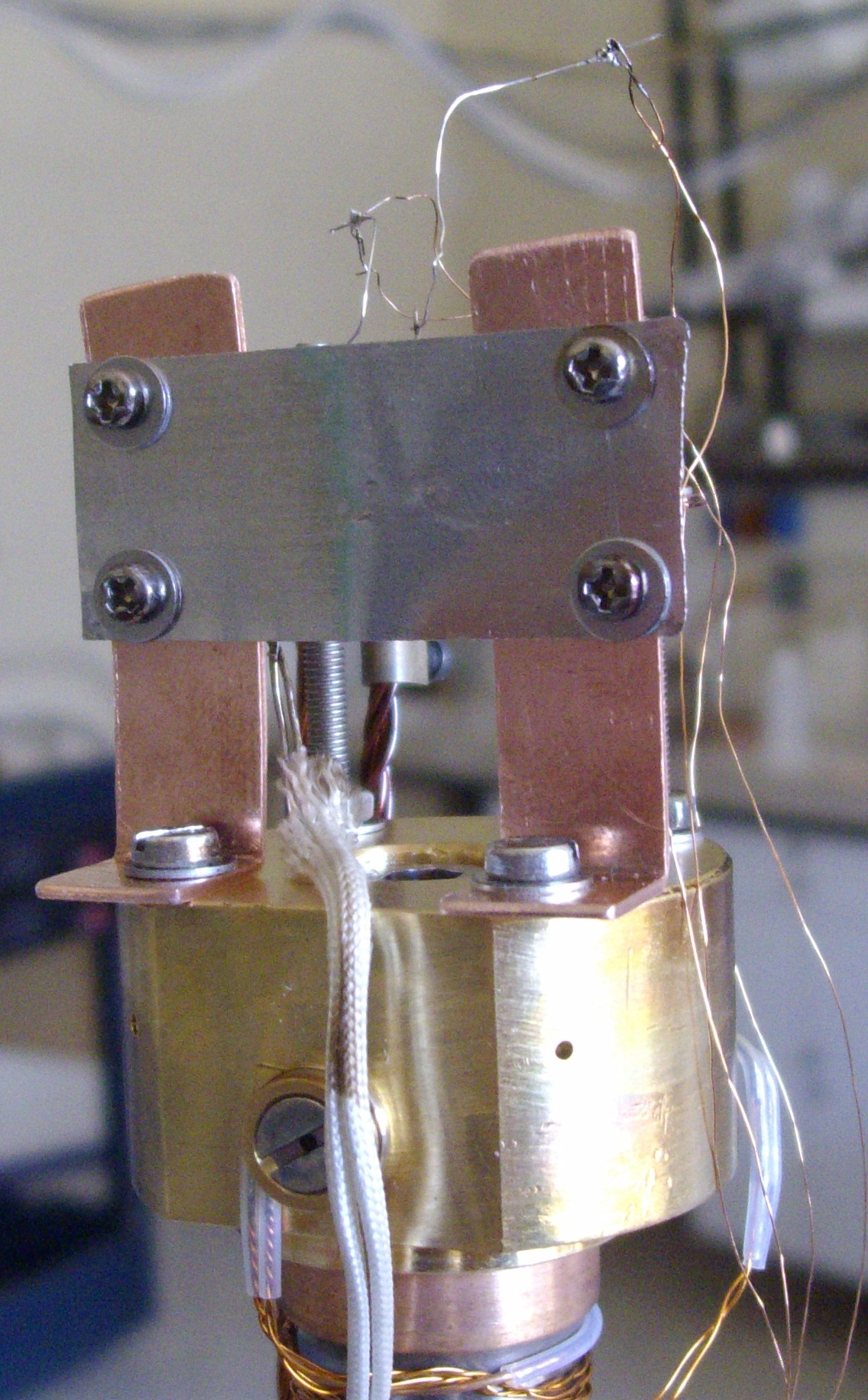

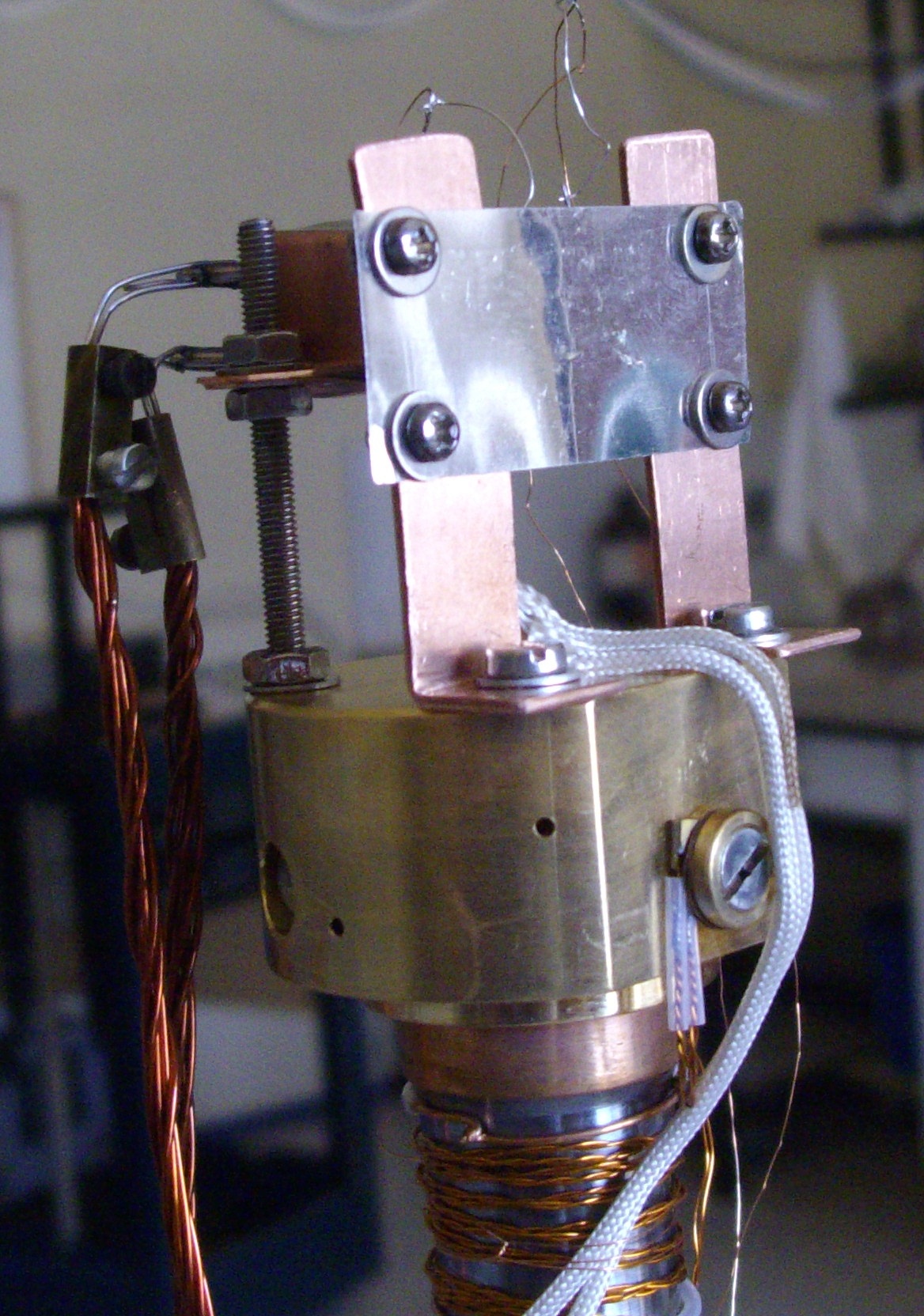

Close-up views of the He closed-cycle refrigerator head with the Pt sheet (sample) fitted with Pt temperature sensor, thermocouple and set of 4 tungsten heater filaments. (September 2007)

The mercury manometer is attached via a piece of flexible tubing for ease in manipulations during pumpdown.

The transparent reservoir for the liquid and the wooden base for the cold bath are also visible.

Readout of the tube temperature.

Tube heater power supply shown on the far left. Next to it stands the power supply for the tungsten wire heaters of the sample.

Digital camera sampling tricks.

20/1/2012:

10/6/2013: Recording the damage inflicted upon the sample by wrong sequence of events.

14/11/2017: Turbo pump from below

Mechanical vacuum pump maintenance (26/1/2018)

17/6/2021: Machining parts for a new aparatus.

1/10/2021: Semi-assembled new machine.